Bearings and consolidations

| SPECIFICATIONS |

Kazancompressormash and NIIturbokompressor have gained significant experience in engineering and manufacturing of bearings and seals for various compressor types that resulted in over twenty patents received in this field.

BEARINGS & SEALS TYPES

- Hydrodynamic support and thrust slide bearings of various types

- Gas dynamic & hydrodynamic end shaft seals

- Lube oil units & sealing systems

Installation of the "dry" gas dynamic seals is also available for currently operated centrifugal compressors during their retrofit, instead of previously installed oil-filled hydraulic lock. Application of the dry gas dynamic seals provides some additional advantages:

- Availability for any type & size of manufactured compressors

- Complete integration into applied compressor system and manufacturing process

- Correspondence to all customer requirements

- Maintenance and service by the certified specialists trained by “John Crane” (England)

- Quality assurance for all parts and reliable operation

ENGINEERING SERVICES

- Computation, design, testing

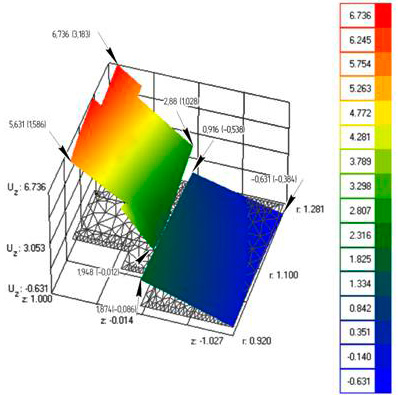

The bearings and seals are engineered using the newest software based on quasi-3D thermoelastic(hydro)dynamic models.

- Engineering, manufacturing and supply of retrofitted bearings for centrifugal compressors fabricated by the Russian companies.

- Recovery and re-manufacturing of support and thrust bearings, seal elements of compressors and turbines of various design.

- Selection and delivery of the lube oil system components (pumps, oil filter) and complete lube oil units, lubrication and sealing systems, selection of lubricants for compressors and refrigerating systems.

|  |  |

|

Gas dynamic seal for centrifugal compressor

|

Control board of gas dynamic seals

|

Lube oil unit of compressor 6GC2-260/2-38 GTU

|