Turbo expanding assembly

| SPECIFICATIONS | DESIGN | REFERENCES |

PARAMETER

- Capacity: up to 15 mln Nwm³/day (625 000 Nwm³/h)

- Suction pressure: up to 1,6 MPa (160 kgf/cm2)

- Discharge temperature: up to -110ºС

- Expansion ratio: up to 3,7

- Differential temperature: up to 70ºС

- Effective capacity: up to 8000 kW

- Bearing type: Active magnetic bearing (AMB) or oil bearing

PROCESS GASES

- Natural gas

- APG

- Process hydrocarbon gas

AREAS OF APPLICATION

- Gas production

- Gas transfer

- Oil processing and petroleum chemistry

- Gas processing

The casing of turbo-expander consists of the removable flow part (RFP) located between compressor casing and expander casing. RFP is a drop-forged casing, with bearings, rotor, adjusted nozzle assembly and gaskets pre-installed.

Upgrade of basic models can be implemented according to customer requirements.

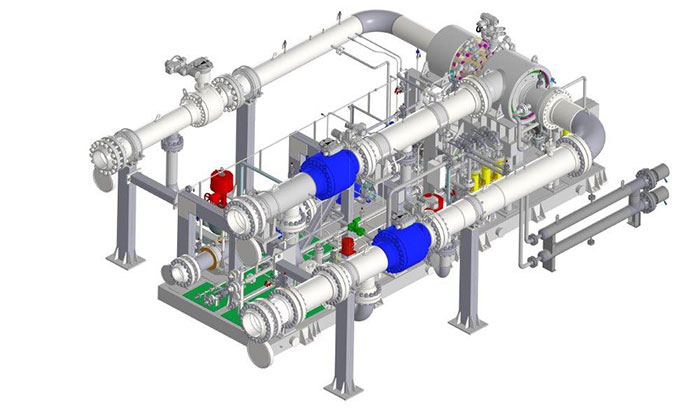

Turbo expanding assemblies include turbo-expander unit, valve assembly and are supplied with gas piping, shutoff and control valves, drainage, hydrate inhibitor supply and buffer gas supply systems. The auxiliary systems unit is mounted on a general base and is supplied with mating flanges and fasteners.

DESIGN FEATURES AND ADVANTAGES

- Active magnetic bearing area (AMB) is separated from the impeller area by shaft seals. Magnetic bearings located in the middle section of the bundle allows feeding of the purified buffer gas and prevents the negative impact of moisture on the AMB windings and sensors.

- Supports in the center of the rotor (cantilever arrangement of the wheels) allows a large diameter in the bearing area, operation at speeds well below the first critical frequency - the so-called "rigid shaft" provides resistance to dynamic impacts on the rotor.

- Implementation of semi-open-type centripetal turbine wheels with a spatial profile of higher efficiency.

- Centripetal wheels ensure the Pt ≤ 3.7 degree of expansion, which allows large temperature drop to 70oC, and as a consequence, a large cooling capacity (depth of condensate extraction, i.e. the efficiency of process units increases)

- Reinforced wheel design provides resistance to liquid phase ingress at the turbine inlet

- Adjusted nozzle assembly for sustainable operation within 50% to 110% gas flow ratio

- The turbo-expander undergoes acceptance testing at the manufacturer's test bench with confirmation of the declared technical specifications prior to delivery

- Design and manufacture of turbo expander assemblies are possible according to individual customer requirements

DESIGN OPTIONS

- Turbo-expanding assemblies to be places in basic facilities of compression shops

- Modular construction with all necessary utilities (modular building)

- Turbo-expanding assemblies for outdoor operation

STANDARD SCOPE OF SUPPLY

- Turbo-expander assembly on skid

- Valve assembly on skid (inlet/outlet insulation valves, quick shut-off valve for turbine and compressor, bypass control valves at turbine and compressor, check valve at compressor bypass (process bypass).

- Active magnetic bearings (AMB), AMB cooling (buffer) gas treatment, adjustment of central forces, methanol supply systems

- Lubrication system (in case of TEA oil design)

- Compressor anti-surge protection

- Automation system

| Name | Operating gas | Capacity, million Nm³/day

(Nm³/h) | Pressure turbo expander MPa | Temperature turbo expander, °С | Rotation speed, rpm | Power, kW | Bearing typ | Dimensions, m | Weight

(in scope of supply), kg | Application

area | ||

| Suction | Discharge | Suction | Discharge | |||||||||

| TDA 5/80 | Natural gas | 5 | 6,63 | 8 | -9 | -20 | 12 000 | 650 | oil | 7х3х3,5 | 30 000 | Gas low-temperature separation |

| BDKA 2-4 | APG | 2 | 3,28 | 1,57 | -45 | -70 | 12 066 | 850 | oil | 9х3,15х3,5 | 40 000 | Gas extraction from NGL |

| Rotors for TDA Rotoflow (USA) | APG | 2,1 | 6,15 | 1,75 | -50 | -101 | 22 500 | 3 000 | oil | 0,8х0,5х0,5 | 1 000 | Gas extraction from NGL |

| Re-engineering and manufacturing of Mafi Trench turbo -expander (USA) | APG | 2,6 | 2,94 | 1,45 | -45,7 | -71,6 | 17 800 | 2 300 | oil | 0,8х1х1 | 5 000 | Gas low-temperature separation |

| Re-engineering and manufacturing of L.A. Turbine turbo-expanders (USA) | APG | 3 | 6,81 | 0,9 | 4,9 | -65,6 | 23 500 | 2 800 | oil | 0,8х1х1 | 5 000 | Gas low-temperature separation |

| BDKA 4.2/15 HL1 | APG | 4,2 | 14,9 | 9,97 | 5,3 | -18 | 22 300 | 1 905 | oil | 12х5,4х7,5 | 75 000 | Gas low-temperature separation |

| MTDA-8.4-9.7 MP UHL1 | Natural gas | 8,4 | 9,7 | 2,6 | -2 | -65,7 | 16 800 | 5 929 | AMS | 11,3х6х3,8 | 60 000 | Gas low-temperature separation |

| MTDA-8.6-9.9 MP UHL1 | Natural gas | 8,6 | 9,9 | 2,6 | -2 | -67 | 16 800 | 6 186 | AMS | 11,3х6,8х3,8 | 60 000 | Gas low-temperature separation |